The term edition binding refers to the binding of a quantity of books as opposed to the one-at-a time type of binding work that is typical in Library Binding, Book Repair and Restoration work.

Click here to generate edition binding templates

HF Group works with many US-based book printing companies to supply their hard cover and soft cover binding needs. Because of the workflow and machinery we have developed in Library Binding over many years, our particular strong niche for edition binding is working with “short-run” lengths from 10 to 2000. We work with some of the premier digital book printers in the country on down to individual self-publishers who want to handle their book production independently.

![]() Click + to read about each of our service offerings.

Click + to read about each of our service offerings.

Soft Cover Binding, at Houchen Bindery Ltd., otherwise referred to as “perfect binding” is performed as a trade service to commercial and book printers, primarily throughout the midwest. Our perfect binding capabilities are offered in 2 distinct methods: EVA perfect binding and PUR perfect binding.

Any soft cover book with coated paper, or needs for heavy usage (such as schoolbooks or workbooks), should be done using our PUR binding. Books with uncoated papers, that do not undergo heavy usage may opt for EVA binding, but our preference is to recommend PUR binding for most projects.

PUR (Poly Urethane Reactive) – the most aggressive adhesive used in commercial binding applications, providing superior page pull strength. Works great with uncoated or coated stocks, even cover stock with coatings or synthetic materials such as book cloth, plastic or UV coating. PUR has a lower freeze point and a higher melting point than all other adhesives used in book binding.

PUR adhesive works well on all types of paper, even aqueous coated stocks or books printed with heavy ink coverage or uncoated papers. This is of enormous benefit to projects requiring short run digitally printed books on highly coated or varnished interior pages – even synthetic materials.

The book on the left is bound using PUR adhesive, and the book on the right is bound using EVA adhesive. Note the thinner bead of glue required with PUR.

PUR Perfect Binding Specifications

Minimum size book block 4 x 5″

maximum size 12 .5 x 12.5″

Thickness – Min: 0.015″, Max: 2.5″

Cover weights: Normal Paper: 50 lb text (81 gsm) up to 12 point (302 gsm)

Coated Paper: 70 lb text (104 gsm) up to 14 pt. (348 gsm)

How to deliver to bindery:

1-up books with 1/8″ extra on all 4 sides. Always use a brightly colored slip sheet divider between each set of books. We can accept loose collated single sheets (from a digital press) or collated, folded signatures (from an offset press).

Collated loose sheets with a slip sheet divider between each set.

Collated signatures with a slip sheet divider between each set of books.

EVA ( Ethyl Vinyl Acetate) – is the standard hot melt adhesive used in regular perfect binding. This works well on regular trade paper backs or textbooks, catalogs, and other perfect bound products. Not as permanent of a solution as PUR, but works well in many commercial applications.

EVA adhesive works well on uncoated paper stocks, but does not have as good of a page pull strength as PUR adhesive. Coated papers will also not hold well over time and with use, and is not recommended to be used with EVA perfect binding.

EVA Perfect Binding Specifications

Minimum size book block 4.125 x 5.25″

maximum size 12 .5 x 12.5″

Thickness – Min: 0.015″, Max: 2.0″

Cover weights: Normal Paper: 50 lb text (81 gsm) up to 12 point (302 gsm)

How to deliver to bindery:

1-up books with 1/8″ extra on all 4 sides. Always use a brightly colored slip sheet divider between each set of books. We can accept loose collated single sheets (from a digital press) or collated, folded signatures (from an offset press)

Hard Cover Binding is performed using many methods of binding or “leaf attachment”, all dependent on quantity, paper style, thickness, page size and end-usage. If you have any questions regarding our options for hard cover case bound editions, please contact us!

PUR Case Perfect Binding ( or PUR adhesive Case bound) is now in wide use for commercial applications with printers and book publishers. PUR adhesive is the most aggressive adhesive for book binding on the market and works well on all types of paper, even aqueous coated stocks or books printed with heavy ink coverage or uncoated papers. This is of enormous benefit to projects requiring short run digitally printed books on highly coated or varnished interior pages – even synthetic materials. Houchen Bindery, Ltd. was the first company in Nebraska (2011) to invest in this technology and now has 2 machine lines offering this capability.

PUR Case Perfect Binding Specifications

Minimum size book block 4 x 5″

maximum size 12 .5 x 12.5″

Thickness – Min: 0.015″, Max: 2.5″

Cover weights: Normal Paper: 50 lb text (81 gsm) up to 12 point (302 gsm)

Coated Paper: 70 lb text (104 gsm) up to 14 pt. (348 gsm)

How to deliver to bindery:

1-up books with 1/8″ extra on all 4 sides. Always use a brightly colored slip sheet divider between each set of books. We can accept loose, collated single sheets (from a digital press) or collated, folded signatures (from an offset press).

With Smyth sewn binding, the thread is driven “through the fold” of a 16 page signature. As you can see in the photos below, these books lay flat very nicely and are used for coffee table-style art and children’s books.

When a press run is in higher (offset) quantity, publishers and book manufacturers look to this method as their first choice. An offset press with a 40″ width can deliver 8.5″ x 11″ size 16 page signatures. When using digital printing, Smyth Sewing will usually not be the first choice because digital presses are better for delivering single sheet collated book blocks rather than signatures. Some extra collation work is required to “nest” 4 page signatures into 16 page signatures required for smyth sewing. There are different types of smyth sewn machines – both manual, semi-automatic and fully automated. Our smyth sewn machine is semi-automatic style, which is good for short run lengths.

Smyth Sewn Binding Specifications

- 16 page signatures are required, with ¼” extra on the high side folio lip

- Book Size: Min size of 4″ x 6″ (portrait orientation) and Max size of 10.5″ x 12″ (portrait orientation)

- Max Size “drop” Landscape: 10.5″

- Do not perforate the spine edge of signatures

Reinforced side sewn binding is a very permanent solution for book blocks both of coated or uncoated papers. The thread sews through the “side” of a book block, taking away 1/4″ of the gutter margin. Our limitation for thickness on this method of binding is about 3/8″. As you can see in the photo to the left, the side sewn binding will not lay flat, but will be held together very securely. This is also an approved Library Binding Institute method. We use this for children’s books, photobooks, year books and many other editions which are less than 3/8″ thickness.

Side Sewn Specifications & Delivery Instructions

Min size book block” 4″ x 5″

Max size: 12″ x 14″

Thickness: Min 0.0875″, Max: 0.375″

Thread sewn in from spine: 1/4″

Gutter allowance: 5/8″

Works well for coated or uncoated papers up to around 3/8″ thickness.

How to deliver to bindery:

1-up books with 1/8″ to 1/4″ extra on top, bottom and face edge + no extra on spine edge . The bindery will side sew in 1/4″ from the edge provided. Always use a brightly colored slip sheet divider between each set of books.

Double Fan adhesive binding (DFAB) is a library binding style method that utilizes polyvinyl acetate glue (PVA), instead of thread for the binding. This binding method places a microscopic bead of glue on either “side” of the pages after notching the spine edge. This creates an exceptional lay flat quality and was developed as a “Smyth Sewn alternative”. We do not recommend an edition to be bound with this method if the interior pages are a coated paper stock such as an 80 or 100 lb text gloss.

DFAB is great for a family history style genealogy edition which will be using uncoated text weight paper on the interior of the book, and requiring a rounded spine edge. One of the big advantages here is it is also ideal for short run lengths. Single sheet collated book blocks such as what you would get from a copier or a digital print stream work great. You can also use folded and gathered signatures with this style of binding.

DFAB binding is an approved Library Binding Institute method, ideal for archival and multi-generational usage such as the huge 1200 page family history book featured here.

DFAB Specifications & Delivery Instructions

Minimum size book block: 4″ x 5″

Maximum size: 10″ x 14″

Thickness: Min: 0.25″, Max: 2.88″

Glue used: Poly Vinyl Acetate (PVA)

White flexible glue, good for uncoated papers

Not recommended for coated papers

How to deliver to bindery:

1-up books with 1/8″ to 1/4″ extra on top, bottom and face edge + a 1/16″ extra on spine edge

for milling and notching. Always use a brightly colored slip sheet divider between each set of books.

Oversewing is an extremely durable, old-fashioned method of page attachment. This method is still popular and is preferable for certain paper stocks and among certain clients. It takes up more of the inner margin of the book than ultrabinding and smyth sewing. Examples of usage are for scientific lab books, industry reference books, comic book collections and more.

Oversewing Specifications & Delivery Instructions

- Minimum book size: 5.5″ x 8.5″

- Maximum book size: 11″ x 14″

- Coated or uncoated papers are OK

- Max thickness: 3″

How to deliver to bindery:

1-up with 1/8″ minimum extra on top, face and bottom edges, Bindery will sew in from the spine edge provided 3/16″. Also allow at least 5/8″ gutter margin to ensure all print and images are visible. Please use a brightly color slip sheet divider between each set.

Hard Cover Case Bound Books can be constructed of many different materials, depending on expected usage and design. Library Binding style books, including most genealogy editions use a more durable material such as Library Summit.

Library Summit covered genealogy edition

Edition Binding materials often have a more “aesthetic” importance, and often use cloths with linen texture, imitation leather look materials, bonded leather or at times, real leather.

Cloth bound special editions featuring fancy European linen-textured cloth.

A trade edition bound using Flar V61 Arrestox B cloth.

A fine edition with custom die foil stamping using Chocolate Brown Advantage 9 cover material.

Printed, laminated covers are very popular with our edition customers. When designing your cover art, it is important to know what spine type and binding method will be employed to make your book. Those factors can affect how the artwork fits on the hardcover. Houchen Bindery Ltd. can print and film laminate your hard cover book using 100 lb gloss text with a choice of Gloss Film Lamination or Soft Touch Matte. We also have a special gloss film lamination with a linen texture. This is sometimes requested on children’s books and textbooks.

Please review our guidelines and information about paper grain direction, and how to prepare materials to be supplied to us for lamination. View Edition Binding Graphic Cover for further information about our selection of spine styles available and templates to help create your own cover.

Soft Strip

This method uses a thin cardstock spine strip, equal to the thickness of the text bulk. This is often used on thicker books with jackets and textbooks. It creates a more “shouldered look,” as the spine is narrower than the front and back case boards.

Hard Strip

A Hard Strip is made from material that is the same thickness as the front and back case boards, but the spine width is slightly narrower than the text bulk. This will create a book with “shoulders” on the front and back case boards also.

Hard strip spine styles can be used with the following binding methods: Ultrabind, Oversew, and Case Perfect.

Hard Spine/Square Back

A Hard Spine/Square Back cover also uses a spine strip which is of the same weight board as the front and back case boards, but the spine is made 3/16″ wider than the text bulk. This creates a “square” look. It is often used on thin cased children’s books, trade editions, and nearly all side sewn books without jackets.

Hard Strip/Square Back spine style can be used with the following binding methods: Side-Sewn, Ultrabind, Oversew, and Case Perfect.

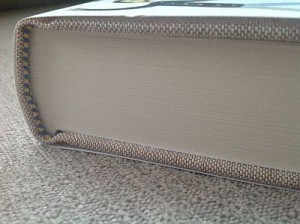

Rounded Back

Rounded back books must be at least 1/2″ thick and will always be made with a soft spine. The rounding machine creates a slight curvature in the spine edge allowing a thicker book to have better open-ability.